Lab 7. - Pump Performance#

Course Website

This laboratory determines performance characteristics of two mechanically identical pumps in various flow configurations.

Readings#

General Readings about Pumps

Videos#

Background#

Pumps are mechanical devices that transfer energy to fluids, enabling them to overcome elevation changes or system resistance. They are used in lift stations to raise fluid from a lower elevation and in booster stations to increase pressure.

Pumps fall into two main categories:

Positive Displacement Pumps: These displace a fixed volume of fluid per cycle, typically providing low flow rates at high heads.

Variable Displacement Pumps (e.g., centrifugal pumps): The flow rate depends on the system’s static head or pressure.

Pump performance is described using curves that include parameters like discharge, head, efficiency, power, and Net Positive Suction Head (NPSH). System hydraulics are represented as system curves, plotting required head versus flow rate. Pumps are selected to match these curves at the desired operating point.

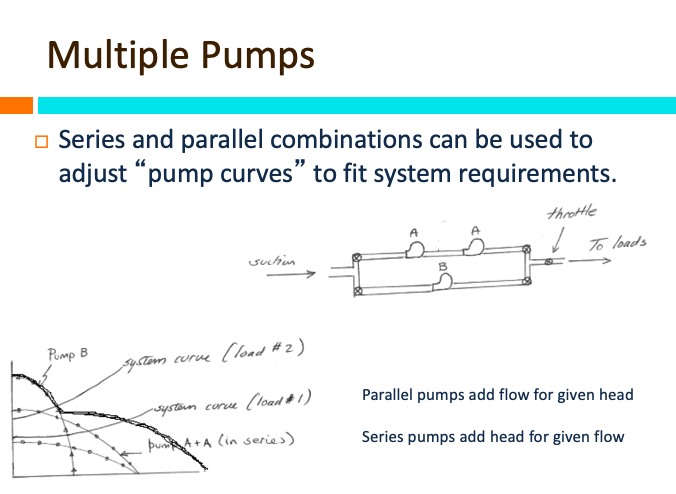

To increase operational flexibility:

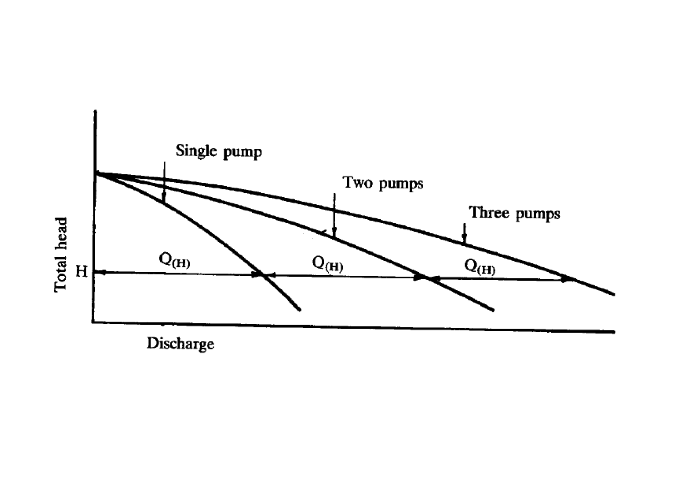

Parallel pump configurations increase flow rates with minimal impact on head.

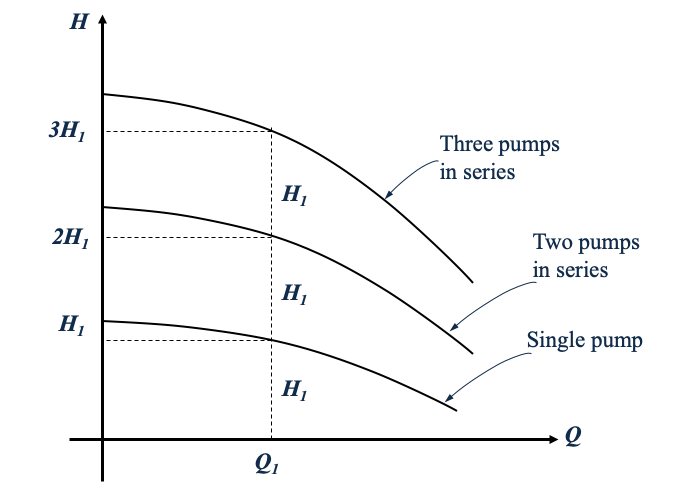

Series pump configurations increase head while maintaining a similar flow rate.

This lab investigates the performance of two identical pumps operating individually, in series, and in parallel configurations.

Pump Hydraulics#

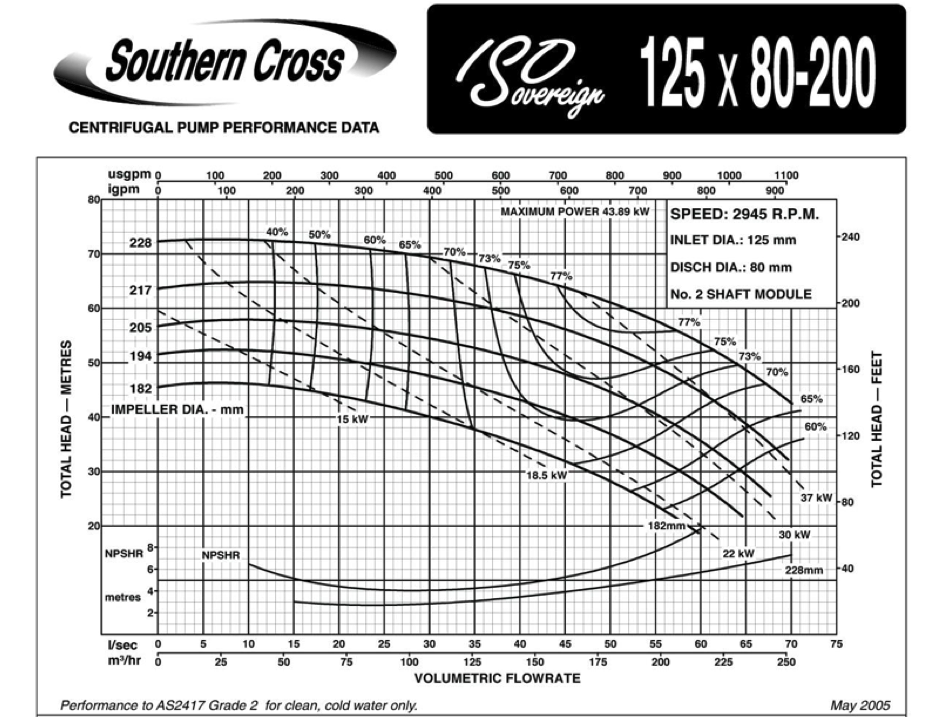

Individual pump performance is based on information from the manufacturer on the performance of pumps in the form of curves. Information typically includes:

discharge on the x-axis

head on the left y-axis

pump power input on the right y-axis

pump efficiency as a percentage

speed of the pump (rpm)

NPSH of the pump

Pumps are selected to match system hydraulics (below) for an effective design.

System Hydraulics#

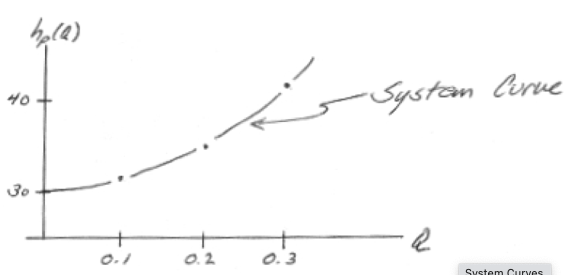

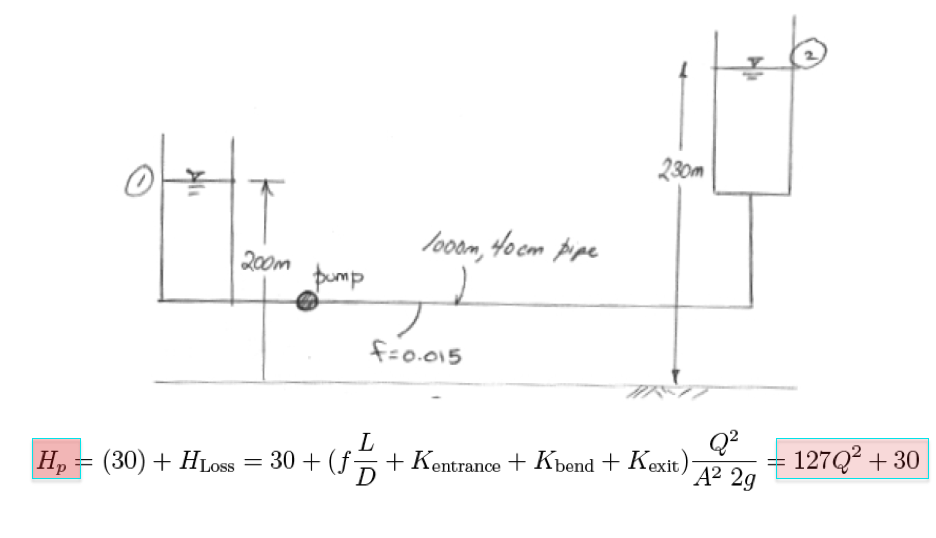

A system (characteristic) curve is a plot of required head versus flow rate in a hydraulic system (H vs. Q) The curve depicts how much energy is necessary to maintain a steady flow under the supplied conditions Total head, \(H_p\), = elevation head + head losses

The system curve is the graphical representation of the system hydraulics such as

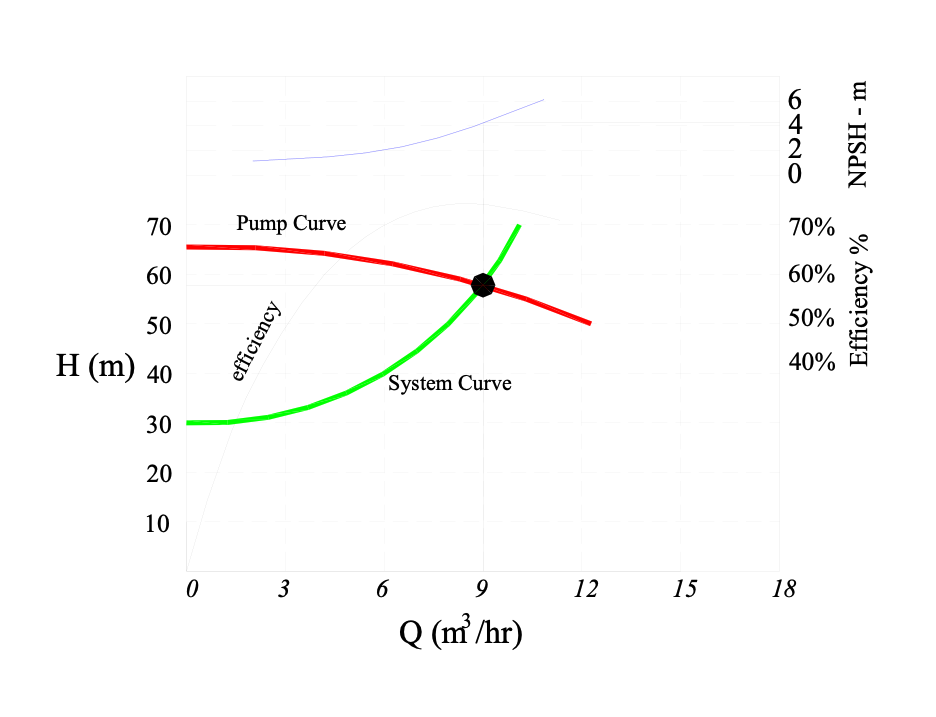

Pump Performance/Selection#

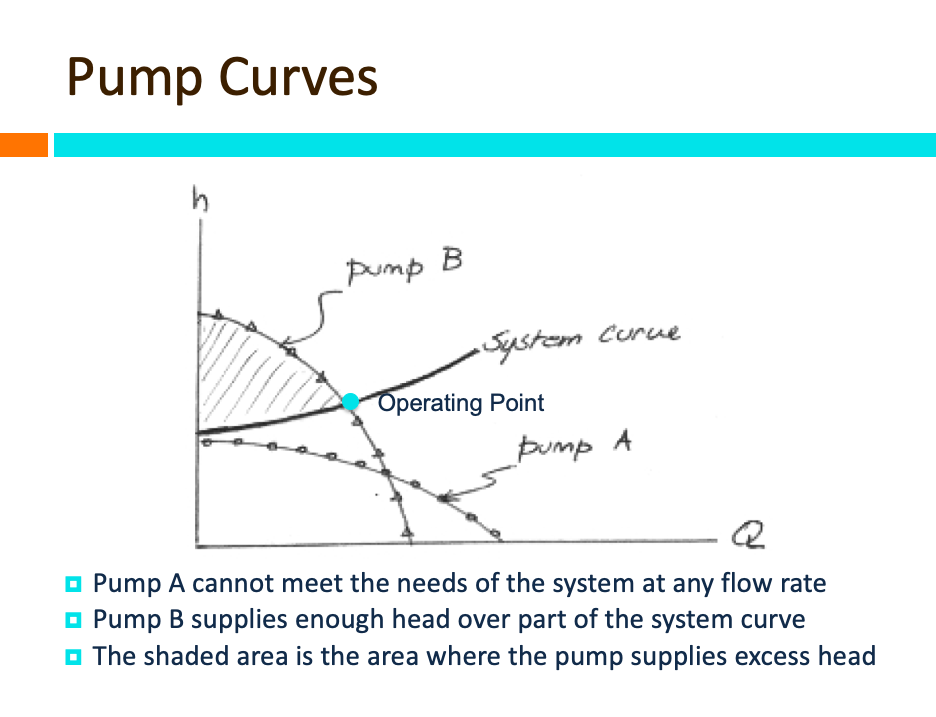

A pump is selected to intersect a system curve at a desired design flow rate (usually a range of flows, but a single operating point is fine for discussion) like in the figure below

Different pumps perform differently

if more flow is desired, usually have to sacrifice added head. If more head is desired usually have to sacrifice flow. Hence in many cases multiple pumps are employed to increase pump station flexibility:

Parallel pumps increase total flow rate at about the same added head.

Series pumps increase added head at about the same flow rate.

Laboratory 7 uses two identical pumps in a flow circuit that allows either pump to operate independently, or both pumps to operate in series, or parallel configurations.

Apparatus Overview#

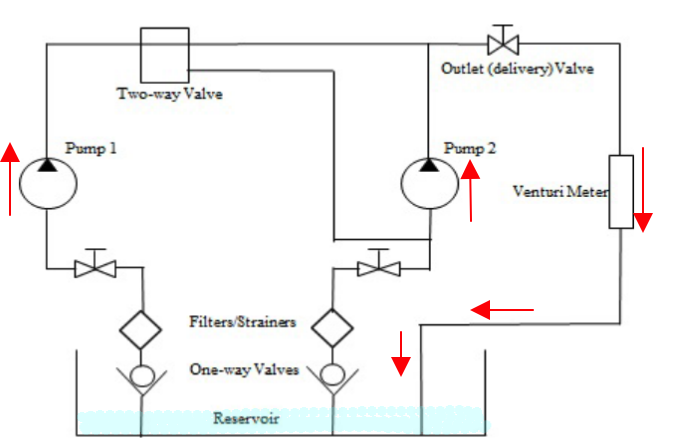

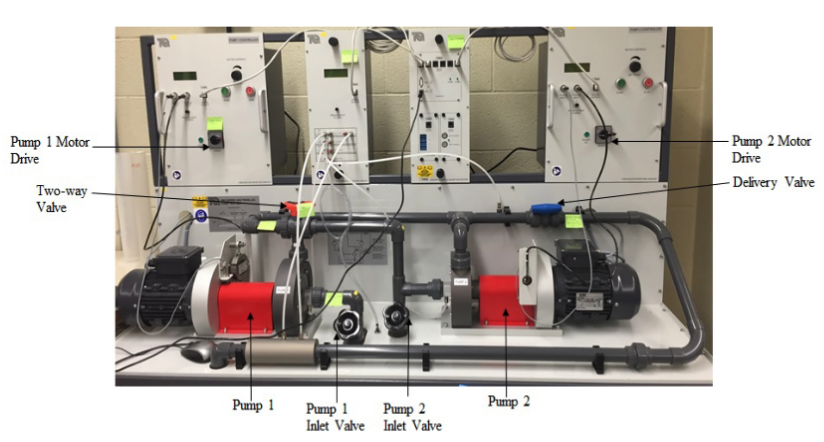

The machine is comprised of two pumps with special arrangements of pipework and valves. It is possible to set the pumps in single, parallel and series connections. Water is pumped from a reservoir through one-way valves and strainers. Water flows through inlet valves, pumps, pipework arrangement and directional valves before it goes through the venturi meter back to the reservoir. Pressures readings at different locations in the pipework and across the venturi meter can be observed in digital display. Flow can be calculated using the venturi meter. The pipe flow schematic is shown below

A photograph of the test station is annotated in the figure below

Total head is related to the pressure change across the pump:

It is the difference between the outlet and inlet pressures for single test (with pump 1).

For the parallel pump it is the difference between the combined outlet pressure and the average of the two inlet pressures.

For the series connection, it is the difference between outlet pressure of the second pump and the inlet pressure of the first pump.

The total input power (mechanical power) is

The motor drive display calculates the power automatically.

The hydraulic power or the horsepower of the pump is

The overall efficiency of the pump is

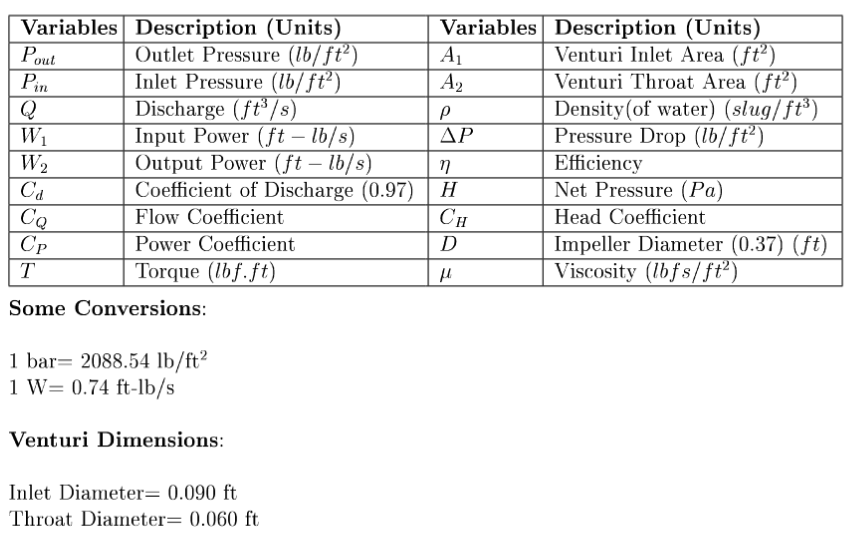

The flowrate can be calculated directly from the pressure drop along the venturi:

Dimensionlal analysis and similarity laws are often used to represent the performance of a morphologically similar class of pump.

The useful dimensionless groups for homologous pumps (similar morphology) are:

\[C_Q = \frac{Q}{ND^3}\]\[C_H = \frac{gH}{N^2D^2}\]\[C_P = \frac{W_2}{\rho N^3 D^5}\]\[Re_D = \frac{\rho N D^2}{\mu}\]\[N \text{ is in radians per second.}\]

These dimensionless groups will allow you to plot your data onto a single chart for a given design, usually Reynolds number is on the horizontal axis and the dimensionless group on the vertical axis.

The relevant variables for the apparatus are:

Deliverables#

Each student group must submit the following deliverables:

Experimental Protocol

Prepare a detailed step-by-step protocol outlining the experimental setup, operation, and safety precautions for testing pump performance.

Include instructions for running the pumps in single, parallel, and series configurations.

Specify the procedure for collecting and documenting data from the commercial ADC system, which records torque, input power, rpm, and head.

Laboratory Report

The report must include the following sections:

Introduction: Brief overview of pump performance testing and the significance of series and parallel configurations.

Apparatus and Methods: Description of the equipment, including the commercial ADC data acquisition system, and a summary of the experimental procedure.

Data and Results: Tabulated data for torque, input power, rpm, head, and flow rate for each configuration.

Performance Curves: Construct performance curves showing head versus flow rate, efficiency versus flow rate, and power versus flow rate.

Analysis: Discuss trends observed in the performance curves and explain the differences in pump behavior in single, series, and parallel configurations.

Discussion: Evaluate how well the experimental results match theoretical performance expectations and comment on potential sources of error.

Conclusion: Summarize key findings and their engineering relevance.

Supplementary Calculations: Include calculations for pump efficiency and power output using the provided equations and data from the ADC system.

These deliverables must be submitted through the course’s learning management system by the specified deadline.