Pipeline Hydraulics¶

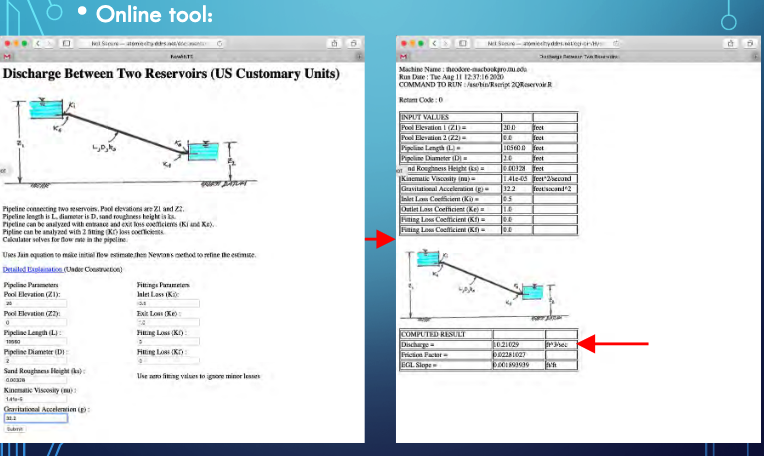

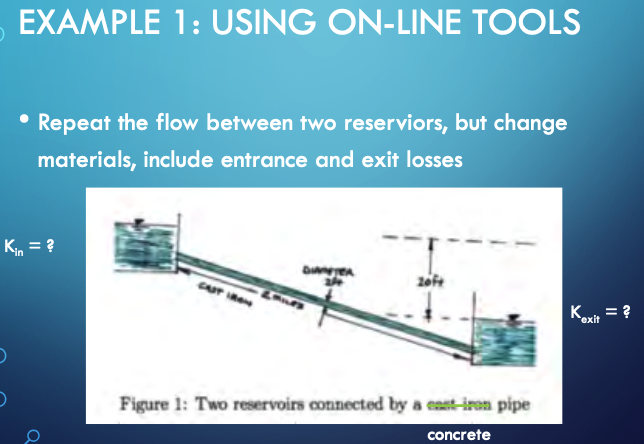

Example: Steady Discharge between Reservoirs (using on-line tools)¶

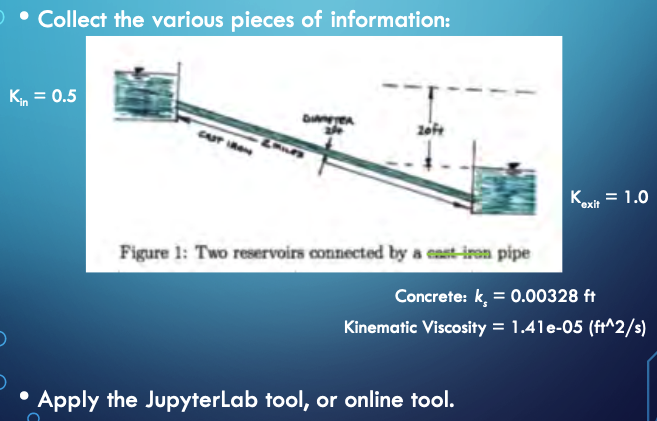

Here we examine a relatively simple hydraulics question - what is the discharge in the pipe for the situation depicted

Problem Statement¶

Known Values¶

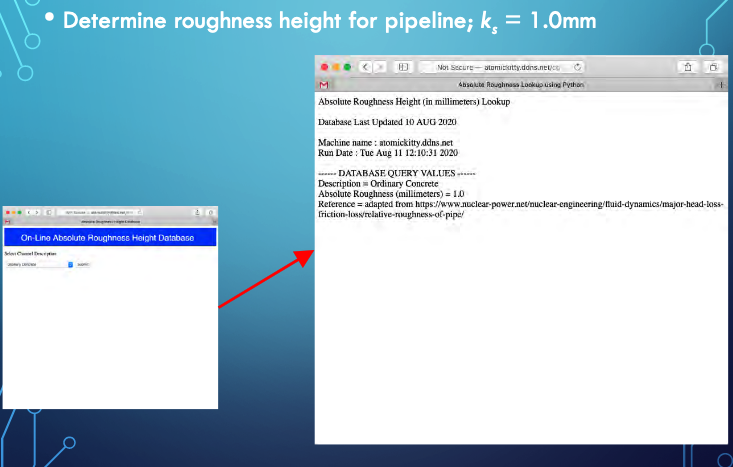

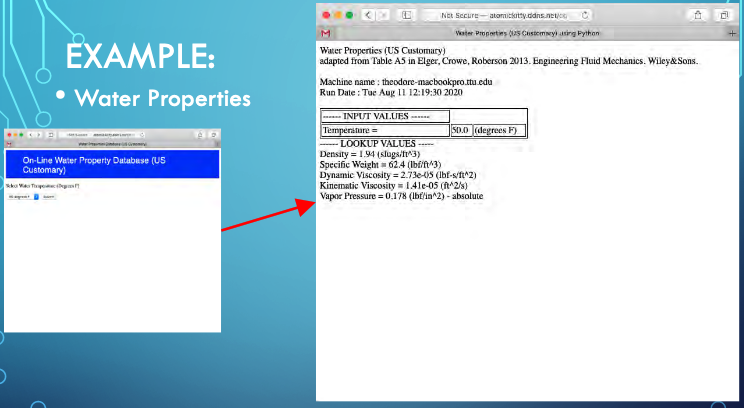

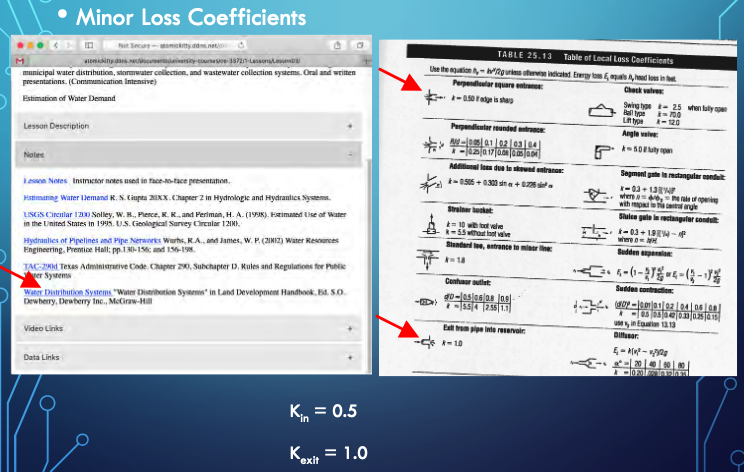

Use tables and references to find known values

Roughness height:

Millimeters to Feet

Water Properties

Minor Loss Coefficients

Consolidate Values for Data Input¶

Or using our Jupyter Script¶

Our script below applied to the same inputs

# modified from getQfromH.py

# ipython module for pipeline hydraulics

# computation engine #########################

# import built in functions for log, sqrt

from math import log,sqrt

# Define the prototype function

def jainQ(pipe_diameter,pipe_length,roughness,viscosity,grabity,head_loss):

egl_slope = head_loss/pipe_length

t1 = sqrt(grabity*pipe_diameter*egl_slope)

t2 = roughness/(3.7*pipe_diameter)

t3 = 1.78*viscosity

jainQ = (-0.965*pipe_diameter**2)*t1*log(t2 + t3/(pipe_diameter*t1))

return jainQ

# values from Example

pipe_diameter = 2.0

pipe_length = 10680.0

roughness = 0.00328

viscosity = 1.41e-05

grabity = 32.2

head_loss = 20.0

# disable above and insert interface engine here

#

# now perform computation and construct output

discharge = jainQ(pipe_diameter,pipe_length,roughness,viscosity,grabity,head_loss)

# Echo inputs, and outputs

print ("Pipe Diameter : ", pipe_diameter)

print ("Pipe Length : ", pipe_length)

print ("Pipe Roughness Height : ", roughness)

print ("Liquid Viscosity : ", viscosity)

print ("Gravitational acceleration constant : ",grabity)

print ("Head loss : ",head_loss)

print ("Discharge : ",discharge)

Pipe Diameter : 2.0

Pipe Length : 10680.0

Pipe Roughness Height : 0.00328

Liquid Viscosity : 1.41e-05

Gravitational acceleration constant : 32.2

Head loss : 20.0

Discharge : 10.24529705017876

Results are close, but not identical. Why? The JupyterLab script did not include the minor loss terms

Linking Systems¶

A hydraulic system can be analysed as a set of linked components to make an otherwise complicated system easier to analyze.

Idea is to decompose into smaller (hydraulically) independent parts, analyze the parts then reassemble (integrate) the parts to answer questions about the whole system

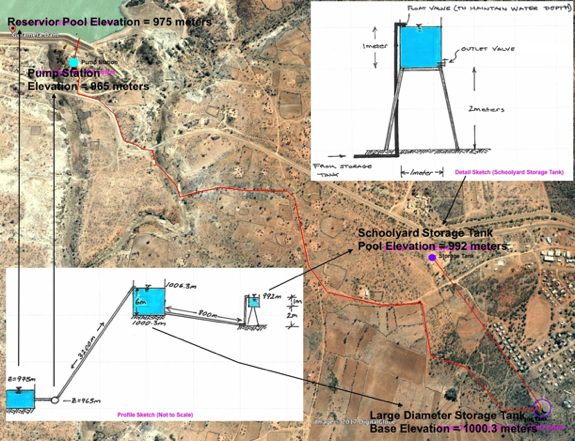

Example: Rural Water Supply to a Village School¶

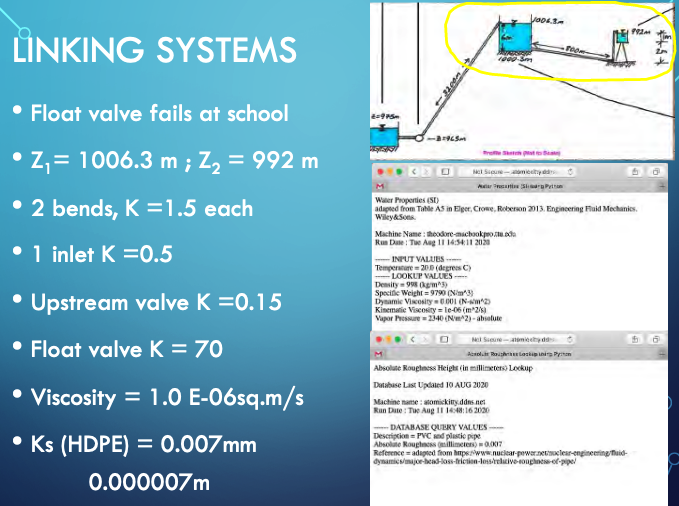

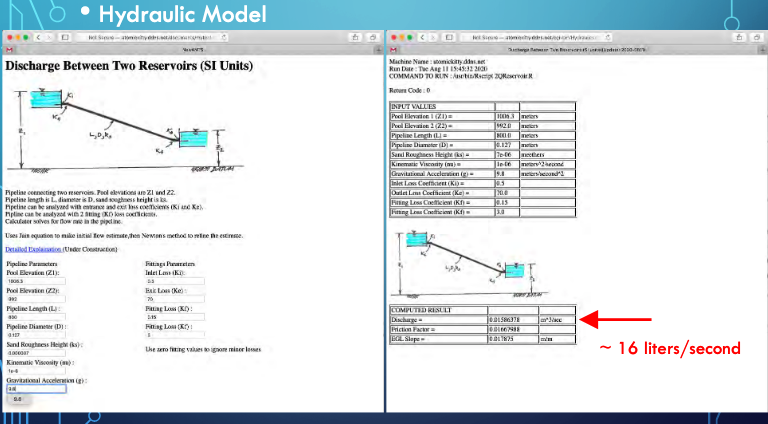

The figure is an aerial image of a pipeline system with preliminary engineering sketches of the system (lower left panel) and a detail sketch of the terminal small storage tank (upper right panel). The 3,200 meter long pipeline lifts 25C water ( \(\rho= 997 kg/m^3\),\(\nu= 8.94 E-7 m^2/s\)) from a treatment plant on the downstream face of Gulameta Dam through a 127 millimeter high-density polyethylene (HDPE) pipe (ks =0.0015 mm) to a large diameter at-grade cylindrical storage tank. A secondary, 800 meter long pipeline carries water from the large diameter storage tank to a small, cylindrical (D = 1 meter), elevated storage tank at the village school. Both storage tanks have float valves to prevent overflow and maintain the indicated water pool elevations.

Analyze proposed system to determine anticipated behavior under various situations:

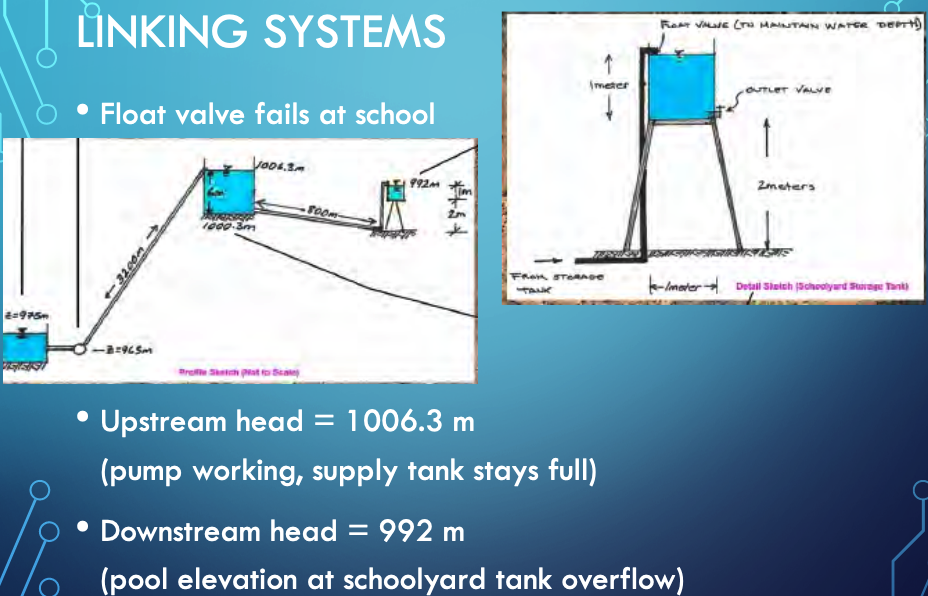

Float valve fails at school

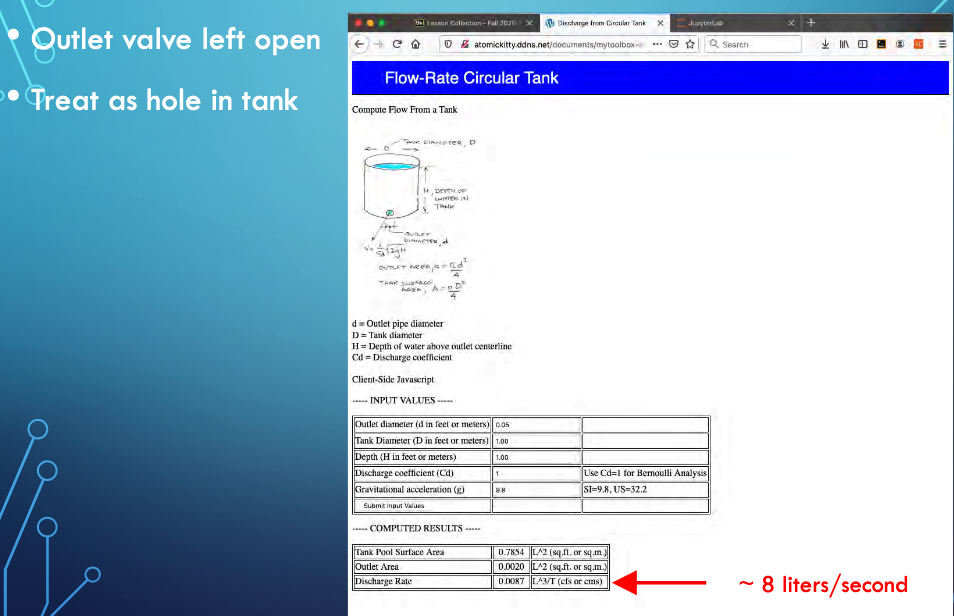

Outlet valve accidently left open

Pump operation under worst failure mode

Pump fails, time until system fails/drains

Float valve limited

Oultet valve limited

Float Valve at School Fails

Get dimensions

Get material properties, and loss coefficients

Apply On-Line Tool or JupyterLab script

The JupyterLab script is shown below, but needs modification for the minor losses. Hence the two values are sort of close, but without all losses the JupyterLab script as shown overestimates the discharge.

# modified from getQfromH.py

# ipython module for pipeline hydraulics

# computation engine #########################

# import built in functions for log, sqrt

from math import log,sqrt

# Define the prototype function

def jainQ(pipe_diameter,pipe_length,roughness,viscosity,grabity,head_loss):

egl_slope = head_loss/pipe_length

t1 = sqrt(grabity*pipe_diameter*egl_slope)

t2 = roughness/(3.7*pipe_diameter)

t3 = 1.78*viscosity

jainQ = (-0.965*pipe_diameter**2)*t1*log(t2 + t3/(pipe_diameter*t1))

return jainQ

# values from Example

pipe_diameter = 0.127

pipe_length = 800.0

roughness = 0.000007

viscosity = 1.0e-06

grabity = 9.8

head_loss = 14.3

# disable above and insert interface engine here

#

# now perform computation and construct output

discharge = jainQ(pipe_diameter,pipe_length,roughness,viscosity,grabity,head_loss)

# Echo inputs, and outputs

print ("Pipe Diameter : ", pipe_diameter)

print ("Pipe Length : ", pipe_length)

print ("Pipe Roughness Height : ", roughness)

print ("Liquid Viscosity : ", viscosity)

print ("Gravitational acceleration constant : ",grabity)

print ("Head loss : ",head_loss)

print ("Discharge : ",round(discharge*1000,3)," liters/sec")

Pipe Diameter : 0.127

Pipe Length : 800.0

Pipe Roughness Height : 7e-06

Liquid Viscosity : 1e-06

Gravitational acceleration constant : 9.8

Head loss : 14.3

Discharge : 21.185 liters/sec

School Outlet Valve Left Open

Treat as a hole in the tank, assume supply side is unchanged and maintains downstream water level

JupyterLab script for hole in tank (future version this book)

References¶

Gupta, R. S. 2017. Hydrology and Hydraulic Systems (4-th Ed). Waveland Press, Inc. pp 633-661

Nickerson G. 2008. “Water Distribution Systems” in Land Development Handbook, Ed. S.O. Dewberry, Dewberry Inc., McGraw-Hill http://54.243.252.9/ce-3372-webroot/3-Readings/WaterDistributionSystems/

Wurbs, R.A., and James, W. P. (2002) “Hydraulics of Pipelines and Pipe Networks” in Water Resources Engineering, Prentice Hall; pp.130-156; and 156-198.http://54.243.252.9/ce-3372-webroot/3-Readings/Wurbs130-198/

Roberson, J.A., Cassidy, J.J., and Chaudry, M.H. (1988) Closed Conduits in “Hydraulic Engineering.” Houghton Mifflin Co. pp. 240-310 http://54.243.252.9/ce-3372-webroot/3-Readings/Chapter5/