Download this file as a Jupyter Notebook@ http://54.243.252.9/ce-3372-webroot/2-Exercises/ES5/ES5.ipynb

ES-5¶

Copyright © 2021 Theodore G. Cleveland

Purpose:¶

Application of energy and pumping concepts; System curve; Operating point

- Compute head loss as function of discharge in a pipe (system curve).

- Determine pump operation point from a pump curve.

- Develop expertise in interpreting output to answer specific hydraulic questions

Exercise 1¶

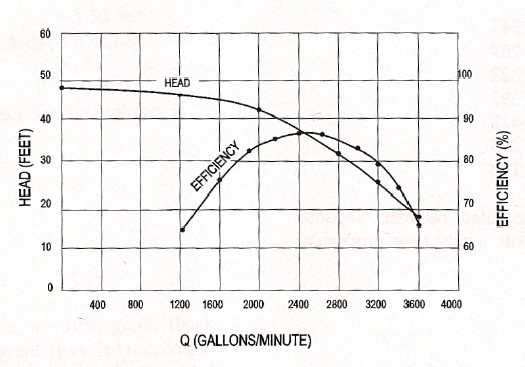

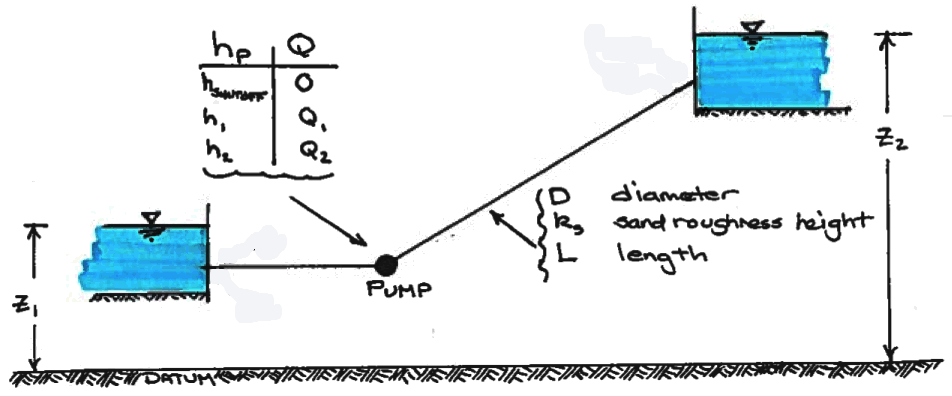

A water supply system draws from a river at an elevation of 800-feet and delivers the water to a storage reservoir at elevation 820-feet. The supply pipeline is a 1000-foot long, 10-inch diameter, cast iron pipe. A single pump with the pump characteristic curve in Figure 1 is used to fill the reservoir.

Determine:

- Sketch the system described in the problem statement.

- Inlet and outlet minor loss coefficients, cite your source of minor loss coefficients.

- The roughness height for use in head loss calculations, cite your source of roughness height.

- The energy equation for the system (system curve).

- The system loss for a discharge of 1200, 1600, 2000, 2400, and 2800 gallons-per-minute.

- Show the calculation of Reynolds number for the different flow rates.

- Show the determination of the friction factors.

- The operating discharge for the system using the supplied pump curve.

- The electric power supplied to the pump to lift the water at the operating point.

Help¶

Exercise 2¶

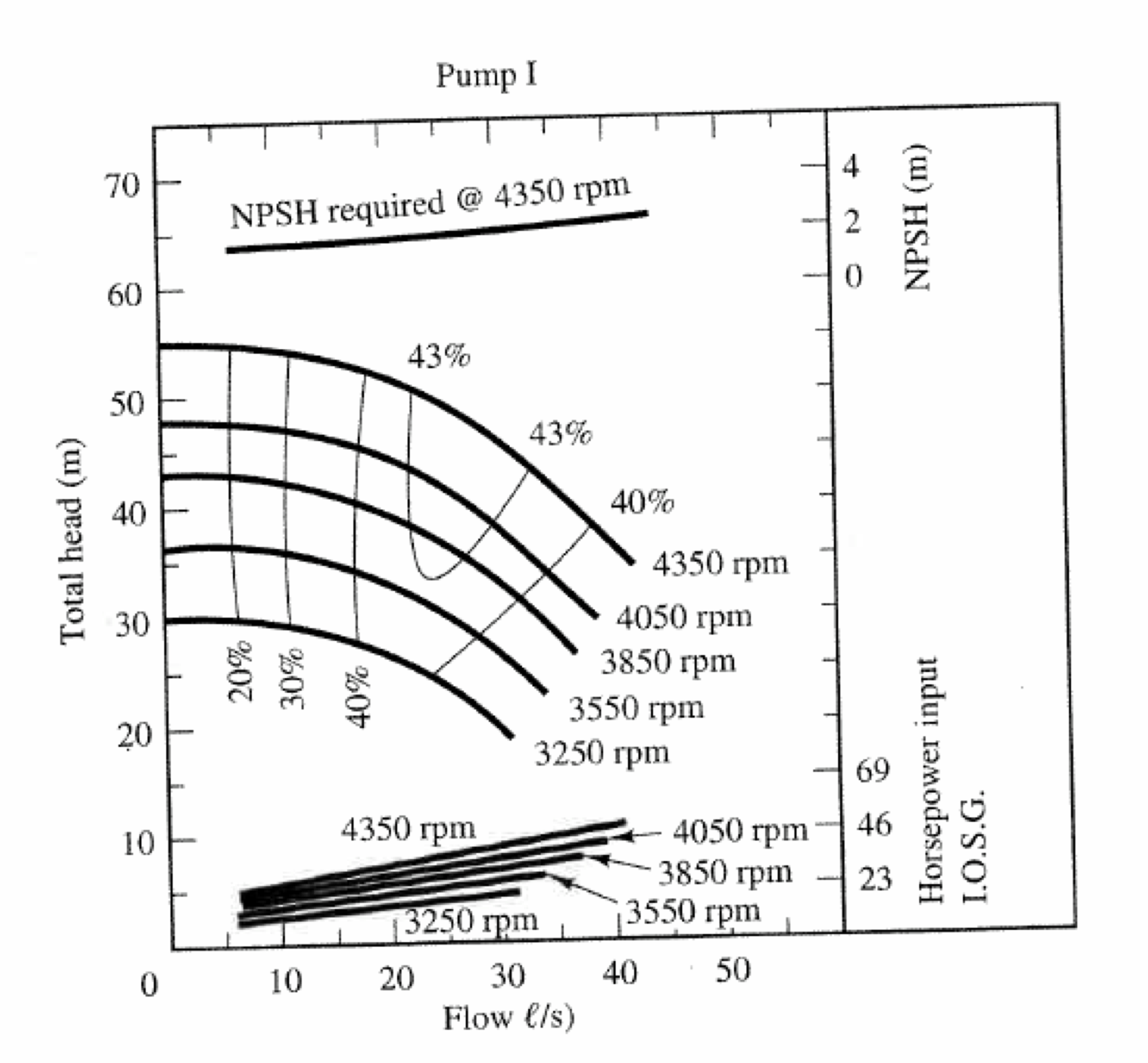

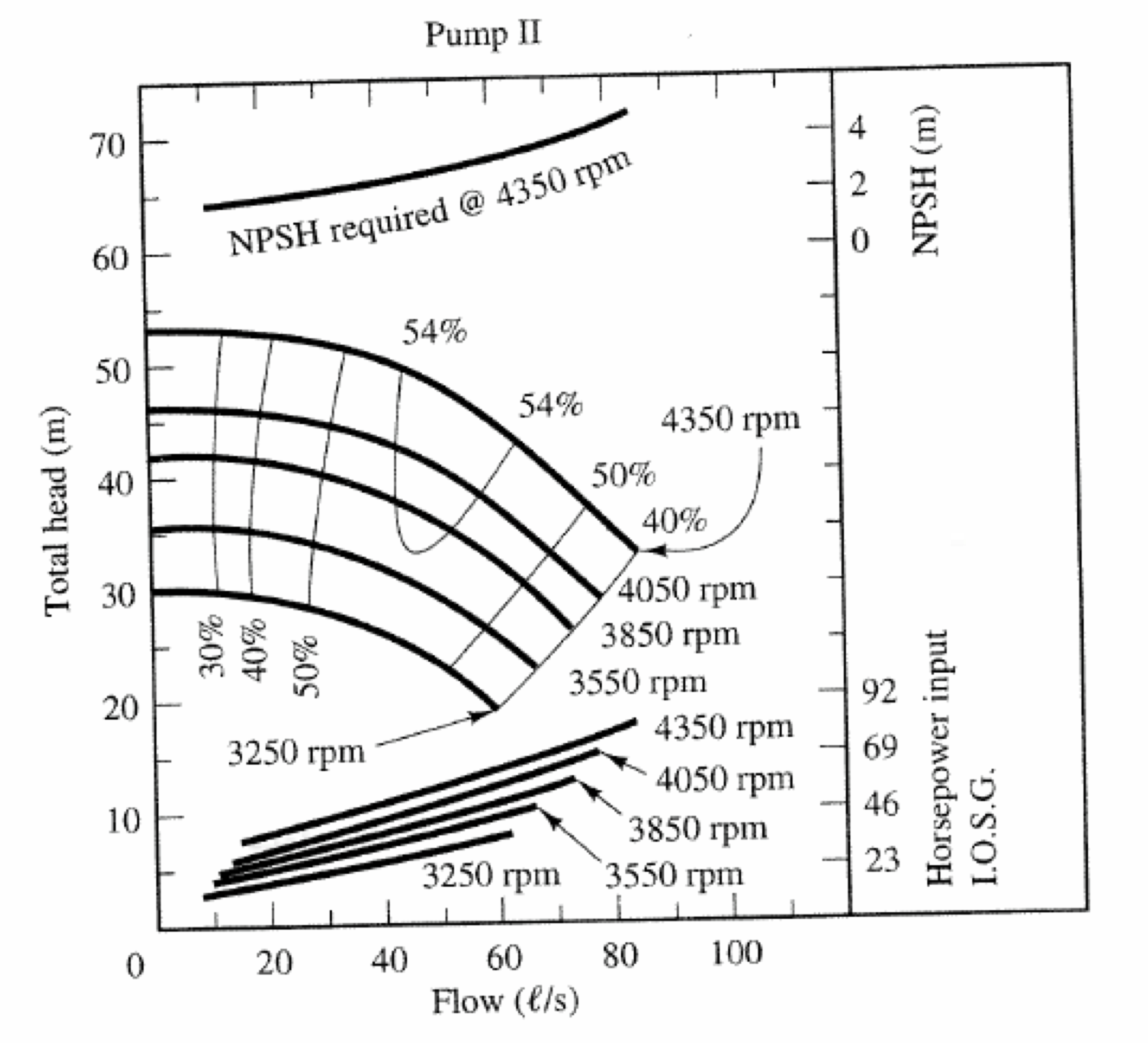

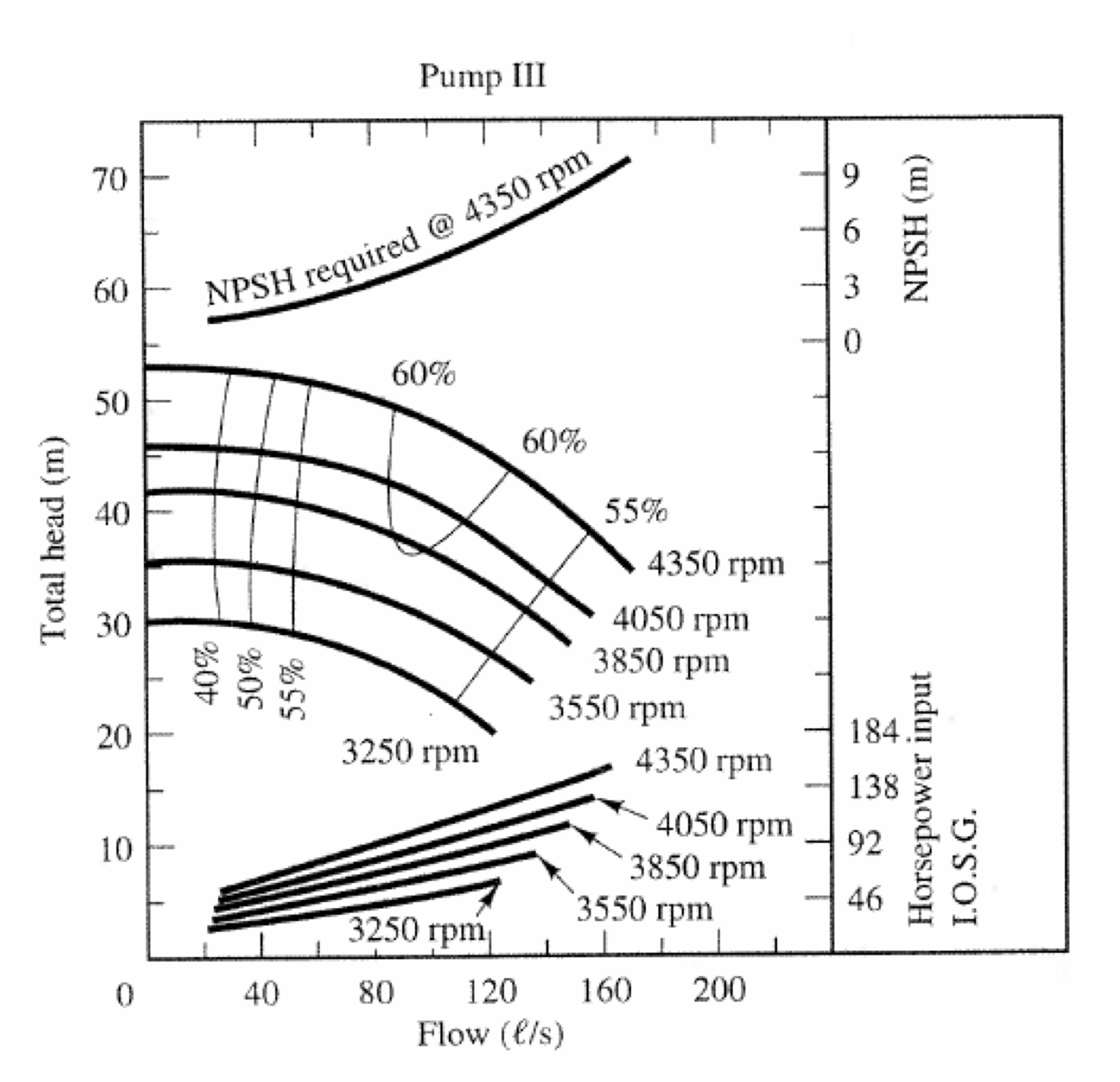

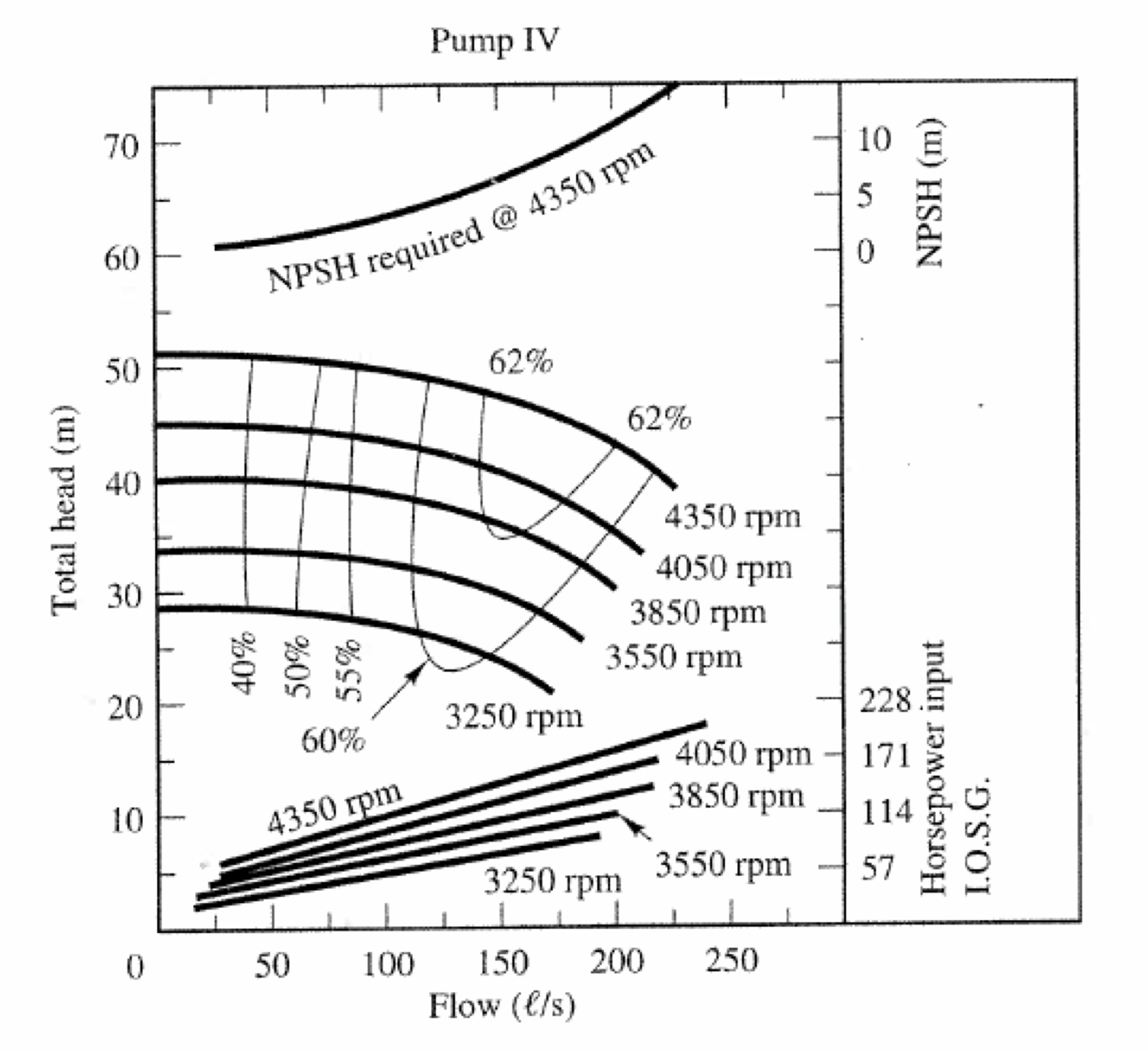

Water is to be pumped at a rate of 70 liters per second in a 1-kilometer meter long, 200 millimeter diameter pipeline between two reservoirs with an elevation difference of 26 meters. A schematic of the system is shown on Figure 2. The kinematic viscosity of water in the system is $\nu = 1 \times 10^{6} m^2/s$ The roughness height of the steel pipe is $\epsilon = 0.045 mm$.

- Select a pump type (from the four curves below) that can supply the required head at the required flow rate.

- Write the impeller speed for the pump in your selection.

- Indicate (label on the appropriate pump curve) the operating point of the pump you selected.

- Estimate the required NPSH for the pump you choose.

- Demonstrate that $NPSH_a > NPSH_r$ for your pump choice.

Deliverables:¶

A brief memorandum with your solutions, showing the requested equations, head loss calculations, and pump operating points.

References¶

- Gupta, R. S. 2017. Hydrology and Hydraulic Systems. Waveland Press, Inc. pp. XX-XX